Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

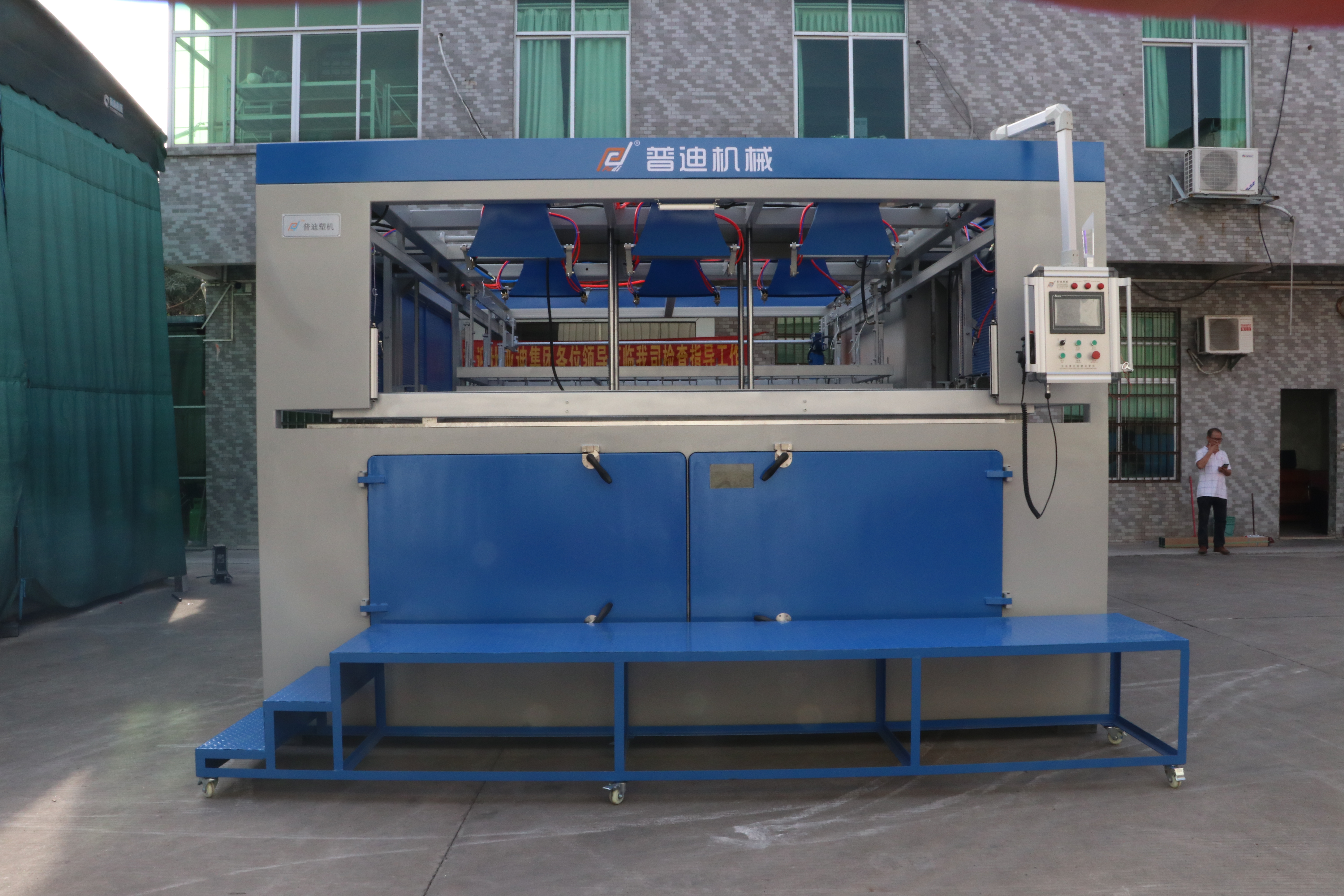

The car roof tent vacuum forming machine can produce the car roof tents fast and efficiently, which can help you to increase the production output and reduce the labour cost. The inner system is advanced, and it can automatically reduce material waste and production costs, to make more money for you. Our wholesale price is in large discount, if you are interested, welcome to contact with us.

Durability:

The material used to produce car roof tents is durable and long-lasting, which means that the tents can withstand harsh weather conditions and provide a reliable shelter for customers. What’s more, the speed of producing is quicker than human, and the quality is better than human, why do not use the machine to substitute of human.

Environmental Friendliness:

Vacuum forming is a relatively environmentally friendly manufacturing process, as it produces less waste than other manufacturing processes. This is important for manufacturers who are looking to reduce their environmental impact, which can better fit the national standard. If your company is serious limited with the emission by government, the machine is worthwhile to have one.

Versatility:

A car roof tent vacuum forming machine can be used to produce a wide range of other products, such as packaging, trays, and other plastic products, which means that you can not only make the car roof tent, you can also make others by the machine with the same principle. This makes the machine a versatile tool for manufacturers who need to produce a variety of plastic products.

Product Parameter:

|

Maximum Wellhead Size |

2600mm*1600mm |

|

Forming Depth |

500 mm |

|

Applicable Material Thickness |

1-10mm |

|

Main Switch |

three-phase five-wire 380V±15V, 50Hz |

|

Heating Power |

Upper Furnace: 128kw; Lower Furnace: 128kw; |

|

Total Power |

280kw (subject to actual conditions, normal use is between 50-70%) |

|

Mold Forming Method |

Concave-convex molding (one-shot molding) |

|

Electric Furnace Power |

Frequency Conversion Motor Drive |

|

Die Power |

Servo Motor (both upper and lower mold tables are driven by servo) |

|

Cooling Form |

Powerful Fan |

|

Heating Unit |

fast medium-wave infrared heating tube, analog voltage regulation and temperature control |

|

Vacuum State |

Matching Large or Small Secondary Vacuum |

|

Upper Frame Structure |

It can be adjusted arbitrarily according to the different mold sizes |

|

Sheet Conveying |

Manual Placement |

|

Product Demoulding and Pick-up |

Air Pressure Blowback Demoulding |

|

Other Functions |

Bubble Blowing, Anti-sag, Large and Small Vacuum |

|

Adaptable Processing Materials |

PP. PC. PE. PVC. ABS. PS and other thermoplastic sheets |

|

Machine Dimension |

3800mm*4600mm*3200mm (excluding the upper mold) |